The management system

of aircraft repair base

The management system had to be created from scratch. When we received the project, planning, management, and accounting were conducted on several platforms and programs (incl. Microsoft Office). Such fragmentation and inconsistency harmed the overall performance of the company.

The management system included three units:

01.

Organisation and monitoring of warehouse stock

02.

Airworthiness maintenance

03.

Overhaul workshop management

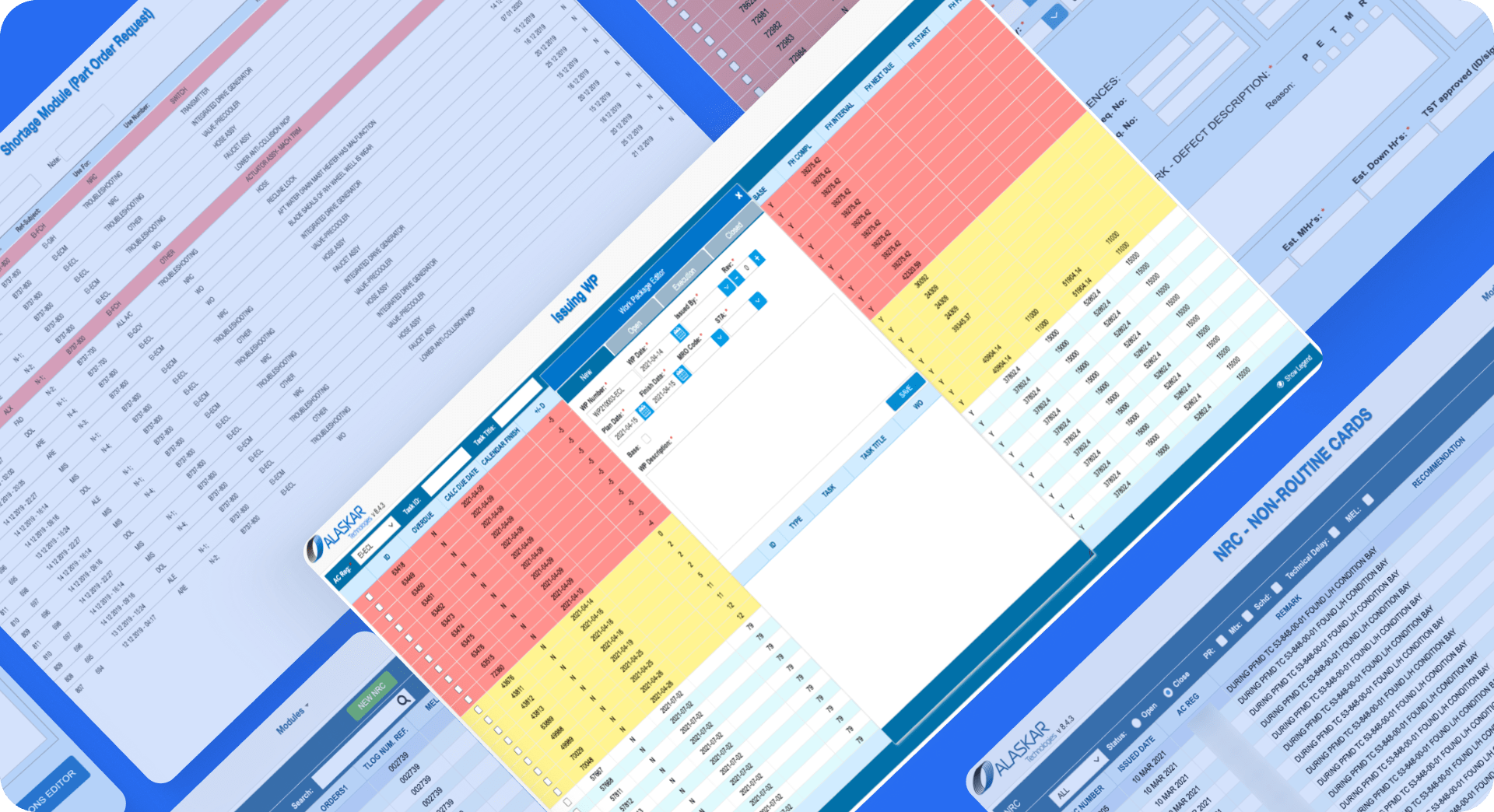

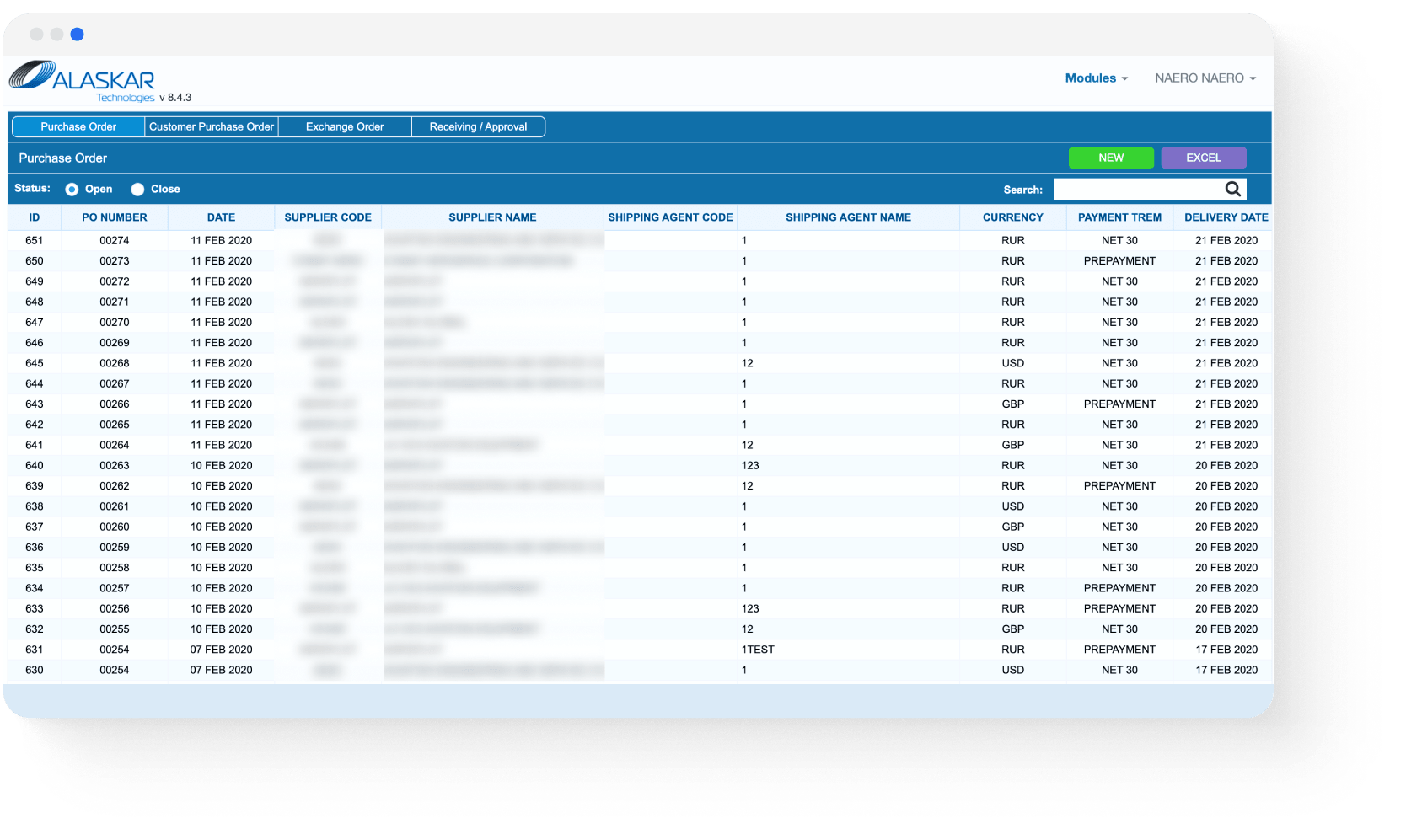

Warehouse logistics software

The key task is to arrange

inventory records,

prepare reports,

and control financial metrics.

The software allows keeping a check on the pot life and monitoring restocking, ensuring no expired materials or simply not in stock. A flexible reporting system allows the customisation of metrics for a certain process or an aircraft. While high operation speed of big data work enables users to use the software to manage the largest aircraft maintenance.

Monitoring of consumption

and material migration

in the company's warehouses

Convenient search

and filtering records

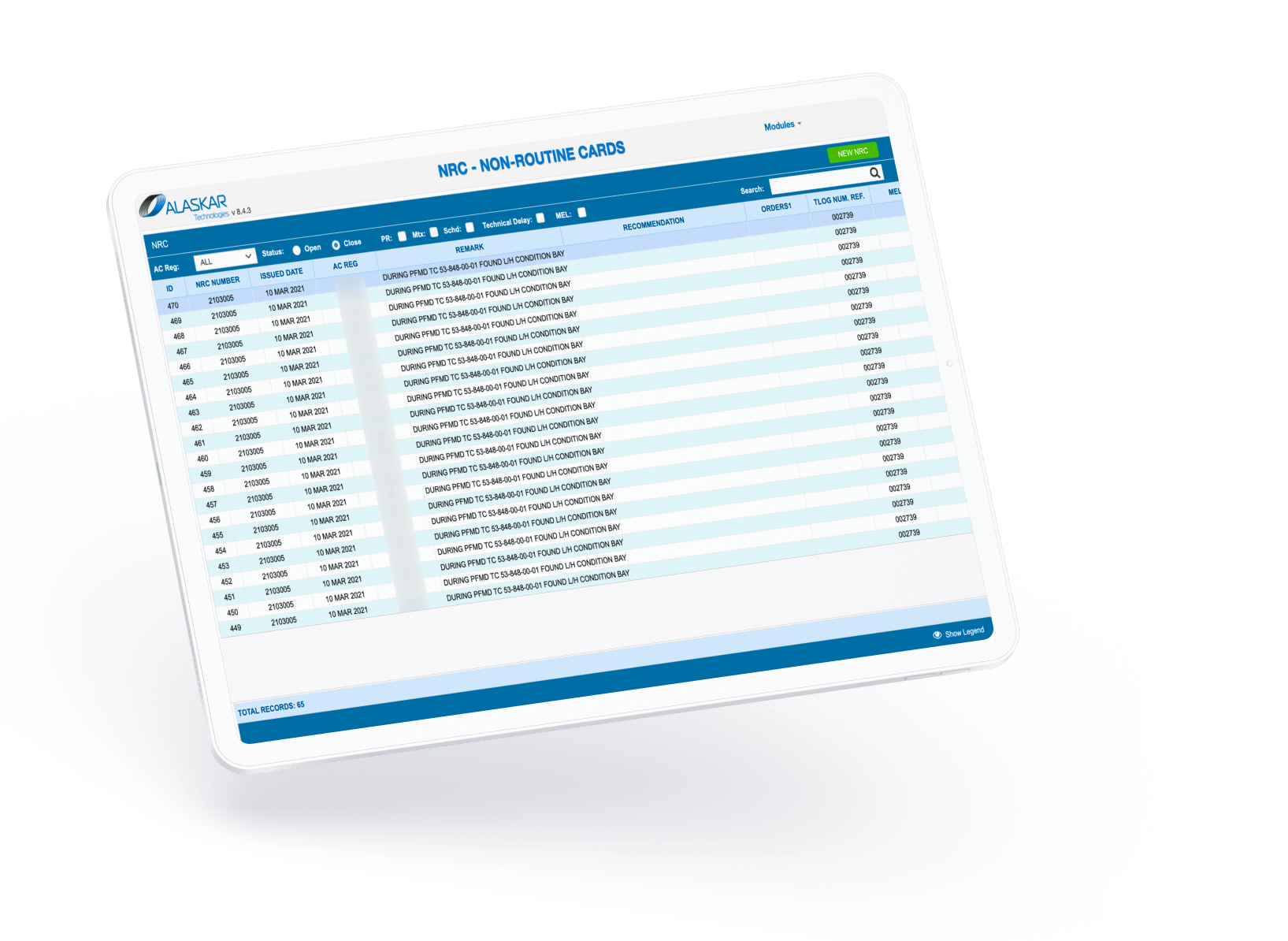

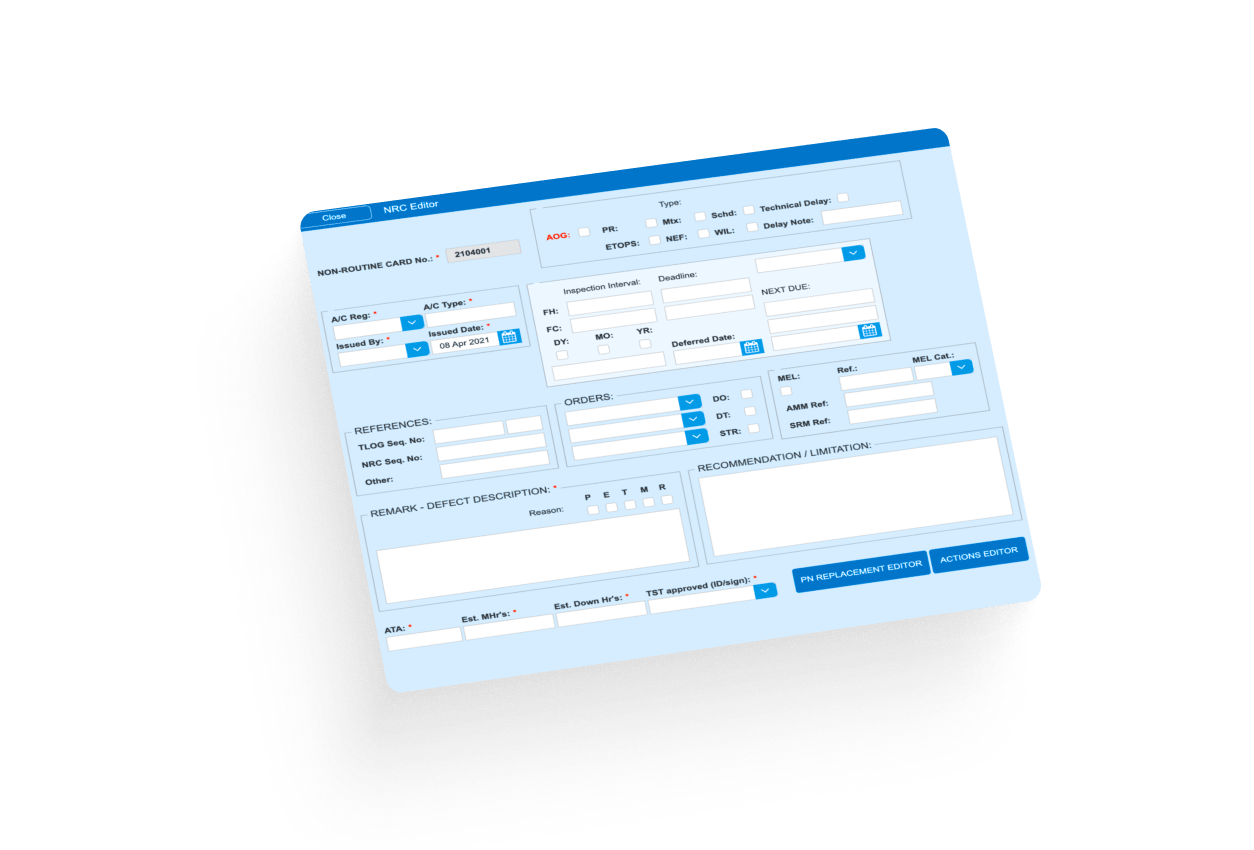

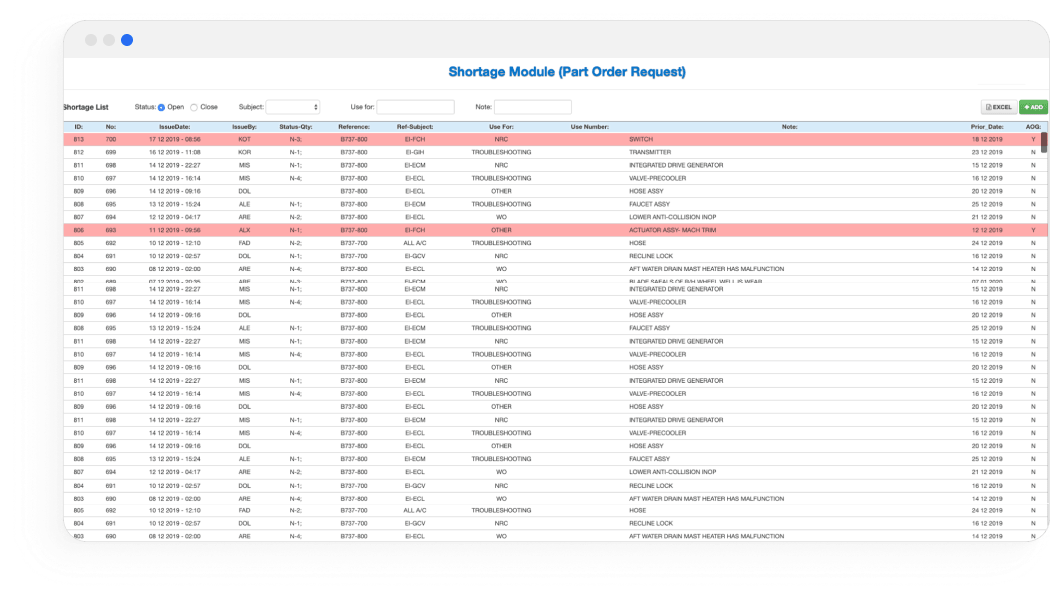

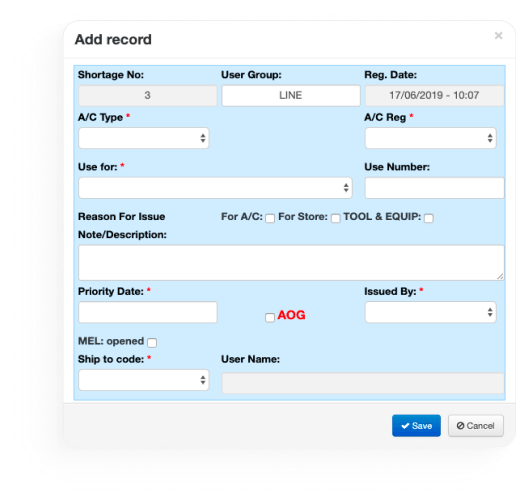

Software for airworthiness maintenance of aircraft.

This unit helps to support

airworthiness maintenance

on the desired level.

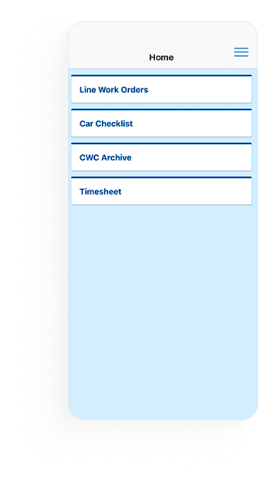

Overhaul workshop management

This tool was created to manage all internal processes of the overhaul workshop. It facilitates editing and printing of repair assignments. The system accumulates all historical and statistical data of employee hours and materials, allowing the solution’s effectiveness fulfilled and current work orders. Record of accomplished tasks is created automatically.

Create and manage

repair orders