кейсы

онлайн-мероприятий

Процессы должны

работать

на результат

Результат работы должен

вызывать

гордость

Чтобы быть лучшими,

нужно постоянно

учиться

У каждого действия есть

цель и смысл

При хорошем

планировании

не бывает

авралов

Обещания нужно

выполнять

В команде все

помогают

друг другу

Критика помогает найти лучшее решение, только

если она

конструктивна

Процесс работы может

приносить

удовольствие

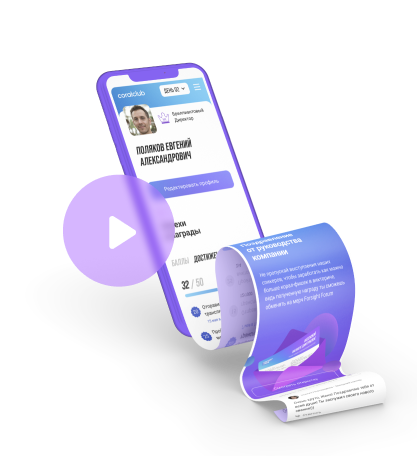

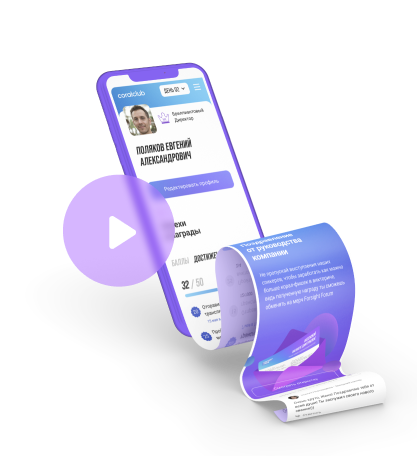

В нашей работе мы практикуем продуктовый подход к разработке, наша гибкая команда всегда ориентирована на результат. Это позволяет нам создавать необходимые рынку нишевые цифровые продукты и отраслевые ИТ-решения: в виде готовых ПО и под кастомизацию.

В дополнение к разработке и интеграции собственных цифровых сервисов BSL предоставляет услуги заказной разработки и аутстаффа.

в которых мы состоим